The Chassis Evolution of the KEYSTONE Drift Kart

At KEYSTONE, we believe that true craftsmanship is proven through time and testing.

AE86 electric drift kart was never just a “toy” project — it was a full engineering journey. Even though we built only one unit, we treated it as if it were a full production model. Over countless tests and revisions, we refined the chassis again and again to achieve the perfect balance between strength, flexibility, and performance.

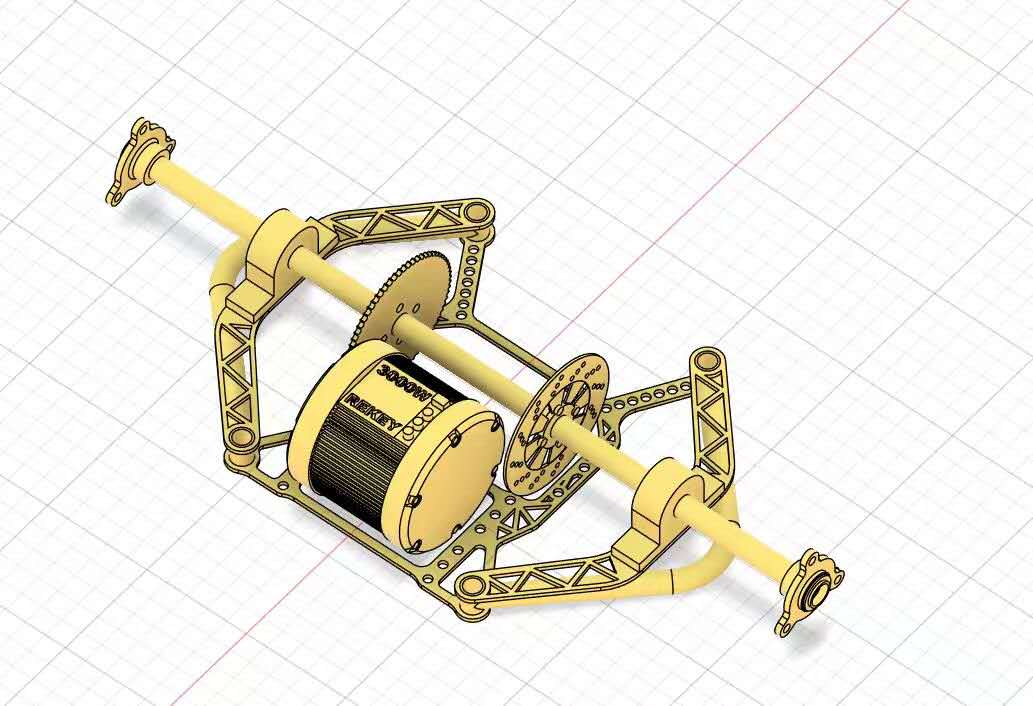

The very first version of the chassis was built using standard steel tubing — simple, functional, but limited. During early tests, we discovered that the frame couldn’t fully handle the torque and stress generated by the 3000W motor. Under heavy load, small flexing and vibrations appeared, which affected the handling precision during drifting.

So we began our first major upgrade: introducing laser-cut components.

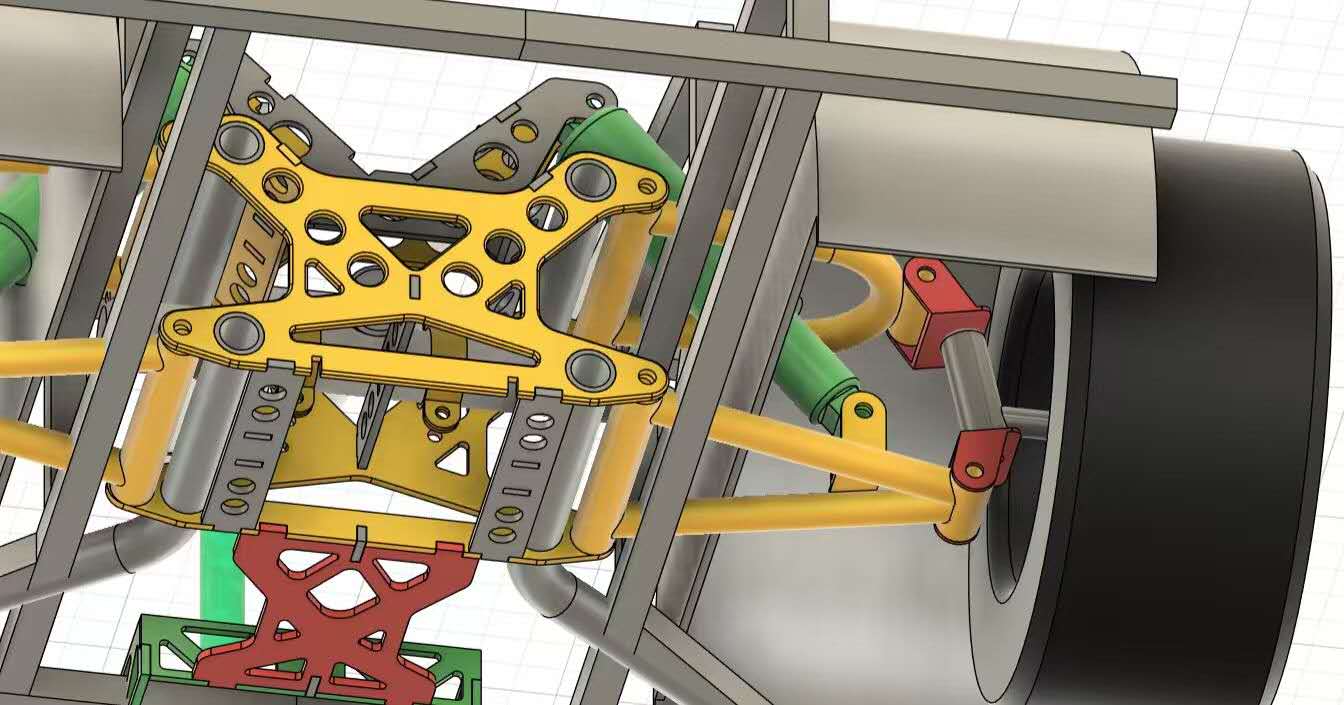

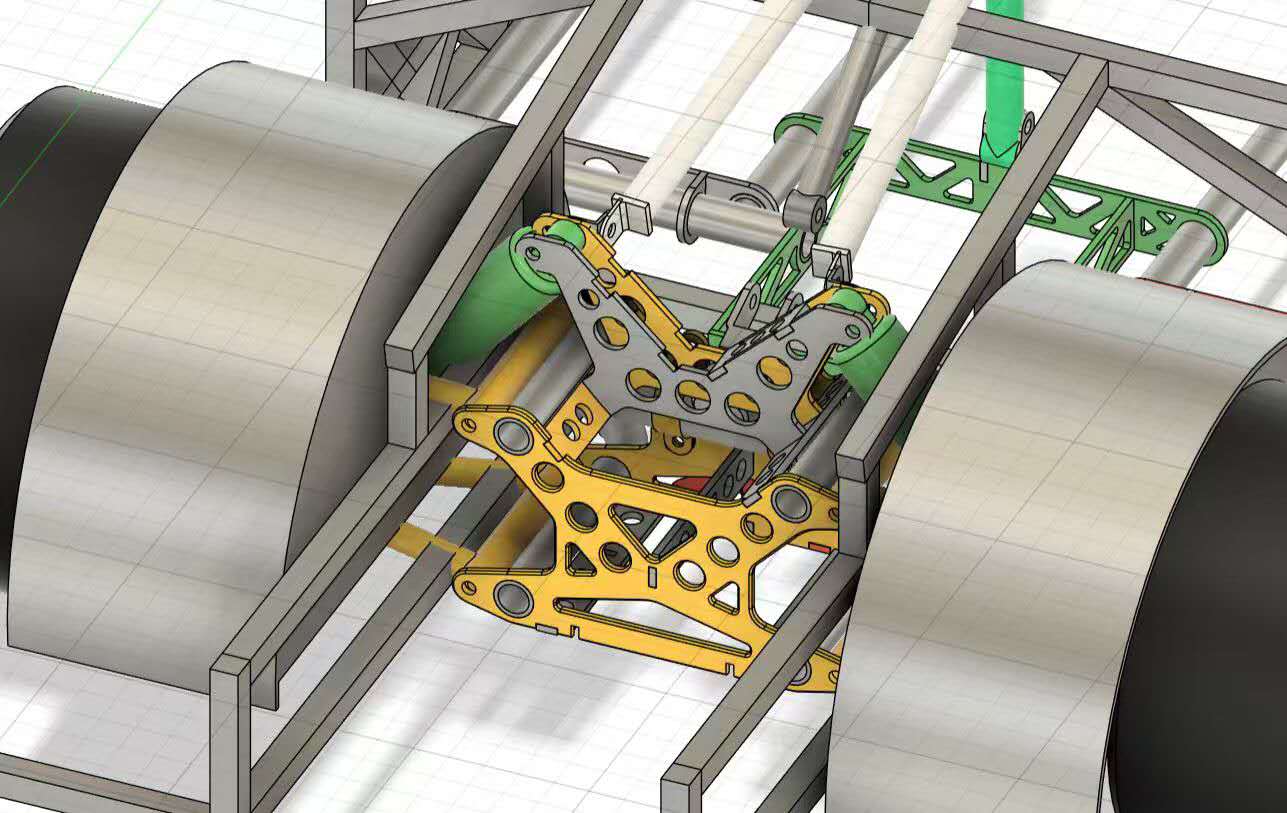

We redesigned the frame, combining laser-cut steel plates with traditional tubing to reinforce high-stress areas. The result was more precision and rigidity, but for us, it was still only a step forward, not the finish line.

Next came the hybrid design phase.

We merged the advantages of both laser-cut structures and tubular frames, creating a modular setup optimized through 3D modeling and stress simulation. Some parts were even 3D printed to test mounting points and fitment before final fabrication.

From the first welded prototype to the fourth complete rebuild, every version taught us something new — from weld angles and weight balance to suspension mounting and steering geometry. What started as a small-scale kart evolved into a true engineering testbed.As the saying goes:

Good things are built to endure.

This little drift kart has become more than just a project — it’s a symbol of our commitment to design, precision, and relentless improvement.

At KEYSTONE, we don’t settle for “good enough.”

We build, test, and rebuild — until it’s right.